Product Description:

The Thermal Spray Powders product is a high-quality powder designed for thermal spray applications, known for its exceptional properties and performance. This dark-gray powder is available in metallic or ceramic compositions, making it versatile for various coating applications.

Chemically, this powder contains a unique blend of Ni 17.5-22%, C 7.5-10%, and Cr, creating a well-balanced formula that enhances its corrosion and wear resistance capabilities. The presence of these chemicals ensures that the coating provides excellent protection against corrosive wear, making it suitable for demanding industrial environments.

One of the key highlights of this Thermal Spray Powder is its impressive hardness range of 1400-1700 HV0.1. This level of hardness signifies the powder's ability to withstand heavy-duty wear and abrasion, ensuring long-lasting durability and performance in challenging conditions.

When it comes to coating materials, the Thermal Spray Powder excels in providing WC-10Co-4Cr compositions, which are widely recognized for their superior quality and reliability. The use of WC-CO-CR coating materials further enhances the powder's effectiveness in creating robust and protective coatings that offer exceptional resistance to wear and corrosion.

In summary, the Thermal Spray Powders product offers a top-of-the-line solution for industrial coating applications, boasting a dark-gray color and a choice of metallic or ceramic compositions. With its unique chemical formula, corrosive wear resistance, and impressive hardness levels, this powder is well-equipped to deliver high-performance coatings that meet the most demanding requirements.

Features:

-

Product Name: Thermal Spray Powders

-

Chemicals: Ni 17.5-22% C 7.5-10% Cr Balanced

-

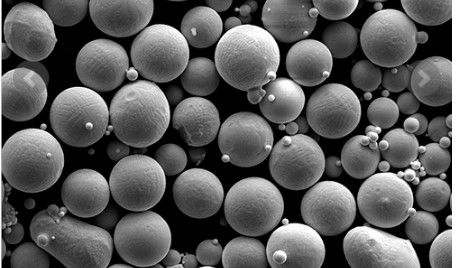

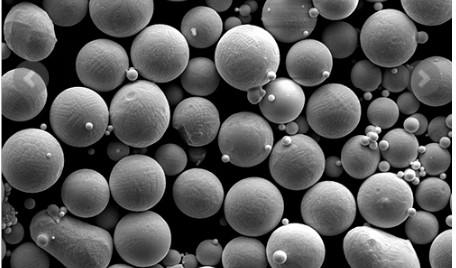

Shape: Irregular

-

Corrosive Wear Resistance: Corrosive Wear Resistance

-

Porosity: 1-5%

-

Apparent Density: 2.9 – 5.8 G/cm3

Technical Parameters:

|

Chemical Composition

|

Metallic Or Ceramic

|

|

Chemicals

|

Ni 17.5-22% C 7.5-10% Cr Balanced

|

|

Typical Hardness

|

1400-1700 HV0.1

|

|

Corrosion Resistance

|

Excellent

|

|

Color

|

Dark-gray Powder

|

|

Porosity

|

1-5%

|

|

Shape

|

Irregular

|

|

Hardness

|

500-2000 HV

|

|

Morphology

|

Angular / Blocky

|

|

Spray Process

|

Flame, Plasma, HVOF

|

Applications:

BODA Thermal Spray Powders, specifically the Fine Size WC-10Co-4Cr model, is a high-quality product suitable for a variety of product application occasions and scenarios. This thermal spray powder is designed for use in coating materials WC-CO-CR, WC-10Co-4Cr, and HVAF WC-CO-CR, making it versatile for different industries and applications.

With its ISO9001:2015 certification, customers can trust the quality and consistency of this product. The minimum order quantity is 50kgs, and the price ranges from $60 to $65 per kg. Each order comes in convenient 50kg drums, with a delivery time of 7-10 days.

The BODA Thermal Spray Powders are ideal for applications requiring coating thicknesses ranging from 20 to 500 microns. The hardness level provided by this product is impressive, ranging from 500 to 2000 HV. This ensures durability and wear resistance in various environments.

One of the key features of this product is its chemical composition, which includes Ni at 17.5-22%, C at 7.5-10%, and Cr balanced. The irregular shape of the powder particles allows for a more uniform and effective coating application.

Thanks to its excellent corrosion resistance, the BODA Thermal Spray Powders are suitable for use in challenging environments where protection against corrosion is crucial. The product's supply ability of 10 tons per month ensures a steady availability for customers with varying needs.

Overall, the BODA Thermal Spray Powders, particularly the Fine Size WC-10Co-4Cr model, offer a reliable solution for a wide range of coating applications. Whether for industrial machinery, automotive parts, or other components requiring durable coatings, this product delivers exceptional performance and value.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!